HVAC Crane Lifts in Tucson: Complete Guide for Commercial Buildings

When you need to install, replace, or remove rooftop HVAC equipment in Tucson, professional crane services aren’t just helpful—they’re essential. Commercial buildings across Southern Arizona rely on Tucson crane services to safely position air conditioning units on malls, office buildings, and industrial facilities without disrupting operations.

At Hook Crane Services, we’ve been lifting HVAC equipment onto commercial buildings in Tucson since 1978. Here’s what property managers and contractors need to know about HVAC crane lifts.

Why HVAC Equipment Requires Professional Crane Services

Commercial HVAC units aren’t like residential systems. Rooftop air handlers, chillers, and cooling towers often weigh between 1,500 and 15,000 pounds. These units require precision placement on elevated surfaces where access is limited and structural integrity is critical.

Common HVAC lifting challenges include:

- Weight distribution: Multi-ton units need exact positioning to prevent roof damage

- Access limitations: Narrow alleys, parking structures, and landscaping restrict crane placement

- Height requirements: Two to five-story buildings demand cranes with sufficient reach

- Time sensitivity: Businesses need minimal downtime during HVAC replacements

- Safety compliance: OSHA regulations require certified operators and proper rigging

Attempting DIY installation or using inadequate equipment puts workers at risk and can damage expensive HVAC units or building structures.

Choosing the Right Crane Size for Your Tucson HVAC Project

Not all crane rentals in Tucson are suitable for HVAC work. The right equipment depends on unit weight, building height, and site access.

Standard Commercial HVAC Projects

17-Ton Boom Truck (90′ boom & jib)

- Best for: Single-story commercial buildings, small rooftop units

- Typical applications: Retail centers, small office buildings

- Weight capacity: Up to 34,000 lbs

- Advantage: Compact footprint for tight urban sites

40-Ton Crane (125′ boom & jib)

- Best for: Two to three-story buildings, mid-size package units

- Typical applications: Medical offices, hotels, shopping centers

- Weight capacity: Up to 80,000 lbs

- Advantage: Versatile for most commercial HVAC projects

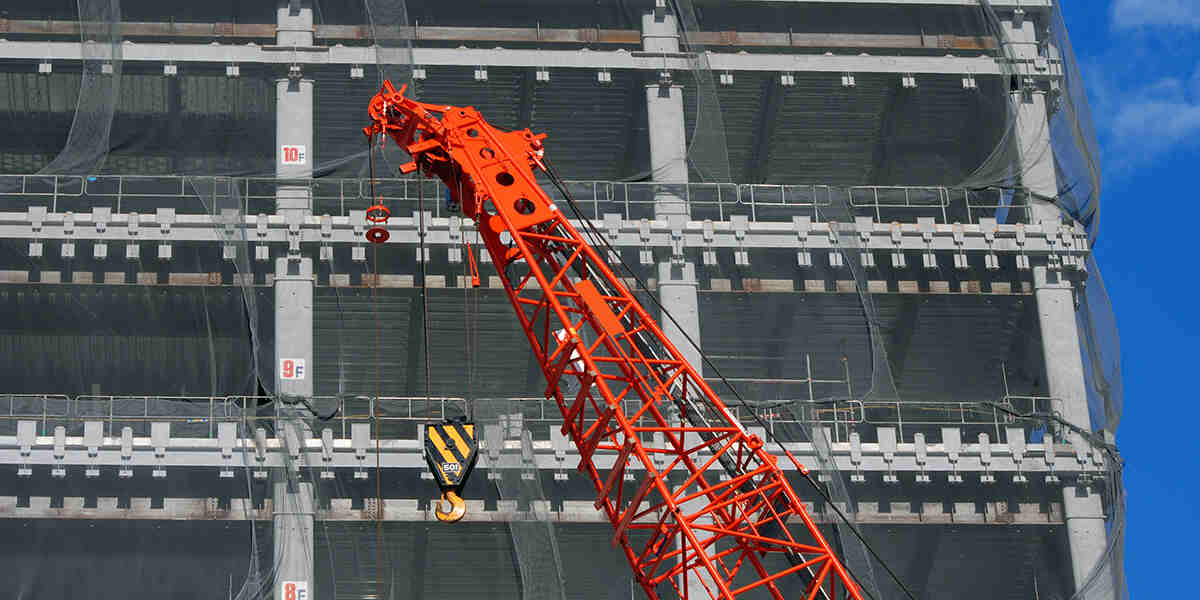

Large Commercial & Industrial HVAC

70-Ton Crane (175′ boom & jib)

- Best for: Large commercial buildings, cooling towers

- Typical applications: Hospitals, manufacturing facilities, malls

- Common equipment: Rooftop chillers, air handlers, cooling towers

- Advantage: Handles the heaviest commercial HVAC systems

90-130 Ton Cranes (201′-235′ boom & jib)

- Best for: High-rise buildings, industrial complexes

- Typical applications: Office towers, power plants, large warehouses

- Special considerations: May require street closures and city permits

Understanding crane lifting capacity helps you select appropriate equipment. Our team assesses your specific HVAC unit dimensions and building configuration to recommend the optimal crane.

Tucson-Specific Considerations for HVAC Crane Lifts

Summer Heat & Scheduling

Tucson’s intense summer temperatures (often exceeding 100°F) create unique challenges for HVAC installations. We recommend scheduling crane lifts during:

- Early morning hours (5-9 AM): Cooler temperatures, better operator conditions

- Winter months (November-March): Ideal weather, lower demand

- Spring/fall (April-May, September-October): Moderate temperatures

Peak cooling season (June-August) means emergency replacements require rapid response. Our 24/7 availability ensures you’re not left without climate control during Tucson’s hottest months.

Monsoon Season Planning

Arizona’s monsoon season (June-September) brings sudden thunderstorms, high winds, and dust storms. Safe crane operations require:

- Weather monitoring leading up to scheduled lifts

- Flexible rescheduling for wind speeds above 20 mph

- Covered equipment protection during dust storms

- Morning lift scheduling before afternoon storm development

Urban Site Challenges

Tucson’s commercial districts present access challenges:

Downtown & Midtown: Narrow streets, overhead utilities, limited staging areas Business parks: Landscaping, parking lot access, neighboring building proximity Strip malls: Customer parking considerations, retail operation hours

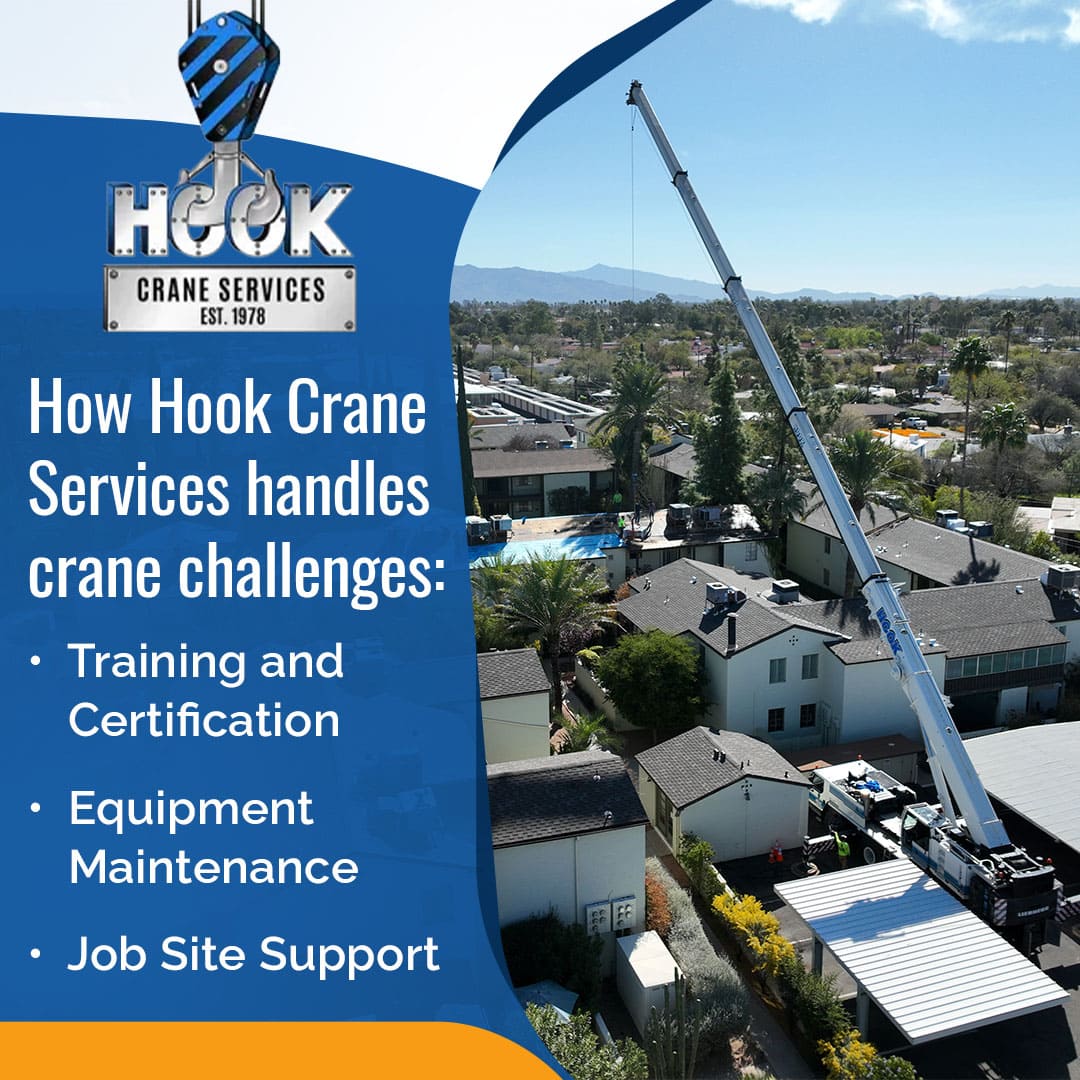

Our NCCCO-certified operators specialize in navigating tight urban environments. We conduct pre-lift site surveys to identify obstacles and plan optimal crane positioning.

The HVAC Crane Lift Process

1. Pre-Project Planning

We coordinate with your HVAC contractor, building management, and facilities team to:

- Review unit specifications and weight

- Assess roof access points and structural capacity

- Identify power lines, trees, and overhead obstructions

- Determine street closure or parking restrictions

- Obtain necessary permits for crane operations

2. Site Preparation

Before equipment arrival:

- Ground preparation: Stabilize crane outrigger placement areas

- Access clearance: Remove temporary obstacles, relocate vehicles

- Safety perimeter: Establish restricted zones around lift area

- Utility coordination: Verify clearance from power lines

3. Equipment Setup & Rigging

Our certified operators:

- Position the crane for optimal reach and stability

- Attach specialized rigging equipment designed for HVAC units

- Conduct weight distribution calculations

- Perform test lifts before final positioning

- Maintain constant communication with the ground crew

4. The Lift

Professional HVAC crane lifts include:

- Slow, controlled vertical ascent

- Precise horizontal positioning over roof curbs

- Steady descent onto mounting pads or structural supports

- Verification of unit levelness and stability

- Safe rigging removal

5. Equipment Removal & Site Cleanup

We don’t leave until:

- Crane is safely dismantled and removed

- Site is restored to pre-lift condition

- Old equipment is lowered (if a replacement project)

- Final walkthrough confirms no property damage

Common Tucson Commercial HVAC Applications

Shopping Malls & Retail Centers

Large commercial spaces require multiple rooftop units. We’ve serviced Tucson-area malls with:

- Multi-zone package units (5-10 ton capacity each)

- Centralized air handlers for climate control

- Emergency replacements during peak shopping seasons

Office Buildings

Professional office environments need reliable climate control. Our crane services support:

- Rooftop unit replacements for tenant comfort

- System upgrades for energy efficiency

- Phased installations to minimize business disruption

Medical Facilities

Hospitals and medical offices can’t afford downtime. We provide:

- Emergency 24/7 crane services for critical HVAC failures

- Precision placement near sensitive equipment

- Strict safety protocols for healthcare environments

Industrial & Manufacturing

Large facilities require industrial-grade HVAC systems:

- Process cooling equipment

- Make-up air units

- Industrial exhaust systems

- Clean room HVAC components

Why Choose Hook Crane Services for HVAC Lifts

47 Years of Tucson Experience: We understand local building codes, weather patterns, and commercial property requirements specific to Southern Arizona.

Comprehensive Equipment Fleet: From 17-ton boom trucks to 165-ton cranes, we have the right equipment for any HVAC project, regardless of size.

HVAC-Specific Expertise: Our operators have extensive experience with air conditioning units, cooling towers, chillers, and air handlers.

Transparent Pricing: No hidden fees or surprise charges. Clear quotes before work begins.

Safety-First Approach: Zero-accident record through strict adherence to safety protocols and equipment maintenance.

Responsive Communication Dedicated project coordinators keep you informed throughout planning and execution.

Get Your HVAC Crane Service Quote Today

Planning an HVAC installation, replacement, or removal in Tucson? Hook Crane Services has the equipment, expertise, and reliability to complete your project safely and efficiently.

Contact us today:

- Phone: (520) 323-0963

- Email: HookCrane@HookCrane.com

- Online: Request a free quote

Our team will assess your HVAC crane needs and provide a detailed proposal including equipment recommendations, timeline, and transparent pricing.

For nearly five decades, Tucson businesses have trusted Hook Crane Services for their commercial HVAC lifting needs. Let us show you why we’re the preferred choice for Tucson crane services.